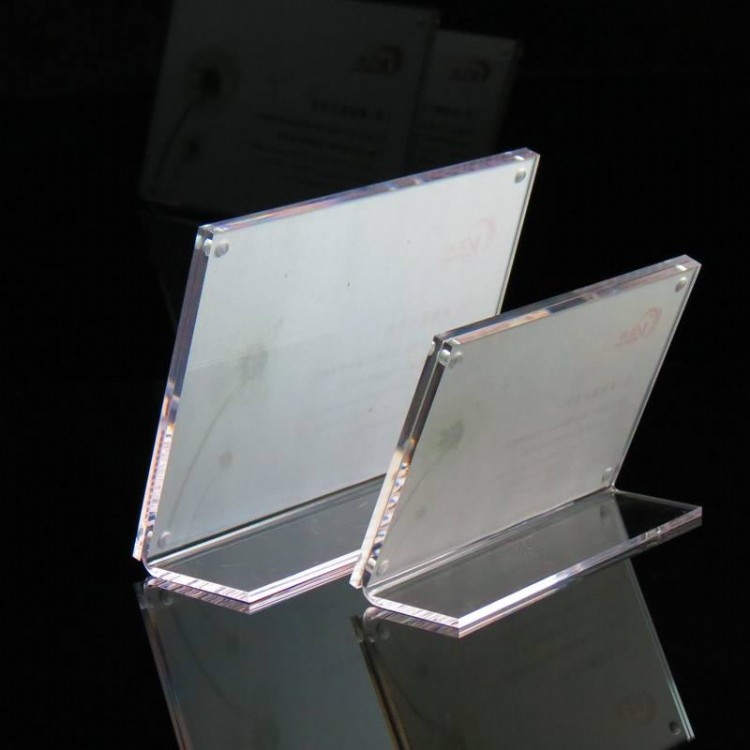

、板材特性:The features of acrylic

1.具有极佳的透明度,抛光后晶莹剔透,透光率达93.7%;Excellent transparency, crystal clear after being polished, light transmittance up to 93.7% ;

2.表面高亮光滑,无异物;highlighted and smooth surfacewithout foreign matters;

3.耐候性、耐温性好,不会褪色失光;goodweathering resistance and temperature resistance without fading and dulling;

4.加工后性能稳定,无异味;stable performance without odor after processing;

安博朗亚克力价值体现:The value of“ABLF”acrylicis reflected in

1.硬度高。具有目前同等产品较高的硬度指标,平均达洛氏硬度(M)值101(详见《化学测试报告》);High hardness.It has the highest hardness index among the sameproductscurrently and its average Rockwell hardness is 101 (see“Chemical Test Report”);

2.板厚精度优异。厚薄公差超过国家标准;Excellent thickness accuracy.The thickness tolerance is much higher than the national standard;

3.异物少。采用多层特殊过滤装置,无尘车间,杜绝杂质掺入的可能。Few foreign matters.Special multi-layer filter unit and dust-free plant are used to eliminate the possible incorporation of impurities.

4.品质稳定。整套流水线采用达到医药纯净标准的全封闭形式运转,恒温作业,保证品质的稳定性。4.Stable quality.The entire assembly line operates in the fully closed form meeting the pharmaceutical pure standard and at a constant temperature to ensure quality stability.

安博朗亚克力性能参数

ABLF Acrylic Parameter

| 项 目 | 检测结果 | 项 目 | 检测结果 |

| 总透光率% | 94 | 拉伸断裂应变% | 6.2 |

| 洛氏硬度(M) | 97 | 拉伸弹性模量 Mpa | 3010 |

| 热变形温度(1.8MPA) | 101 | 维卡软化温度(B50),℃ | 106 |

| 线膨胀系数℃-1 | 7.0*10-5 | 抗溶剂银纹性(4H) | 无银纹 |

| 加热尺寸变化(收缩) % | 1.9 | 简支梁无口冲击强度 KJ/M2 | 21.9(C) |

| 拉伸强度 Mpa | 74.7 |

安博朗进口板材模具规格

(T:2-25mm,随着厚度增加,使用尺寸会相应缩小)

| 净尺寸(mm) | 每架片数 | 净尺寸(mm) |

每架片数 |

| 1240*1840 | 18片/架 | 1380*2620 | 18片/架 |

| 1250*1870 | 18片/架 | 1490*2990 | 13片/架 |

| 1240*2440 | 18片/架 | 2080*3080 | 13片/架 |

| 1250*2470 | 18片/架 | 1850*2450 | 13片/架 |

| 1210*2360 | 18片/架 | 1660*2600 | 11片/架 |

| 1320*2540 | 18片/架 |

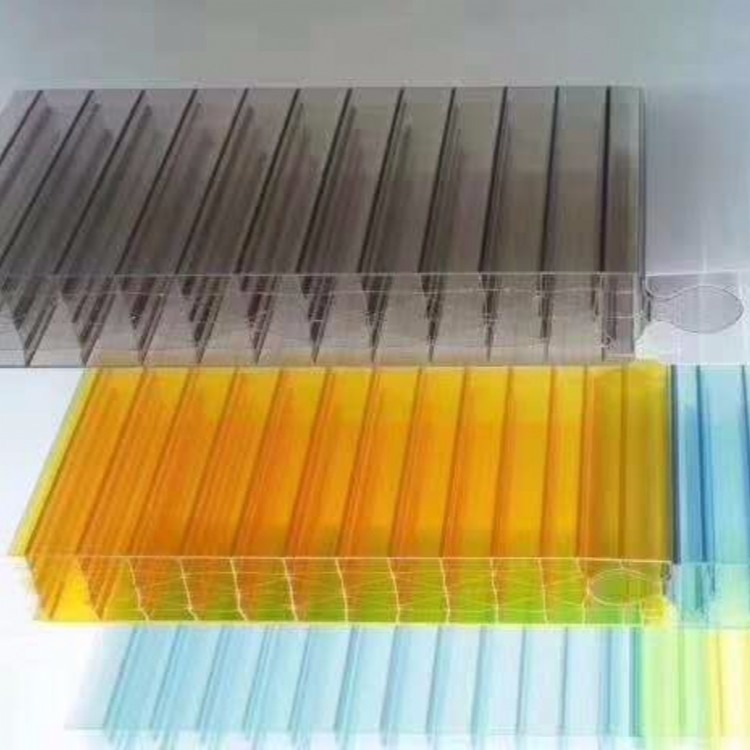

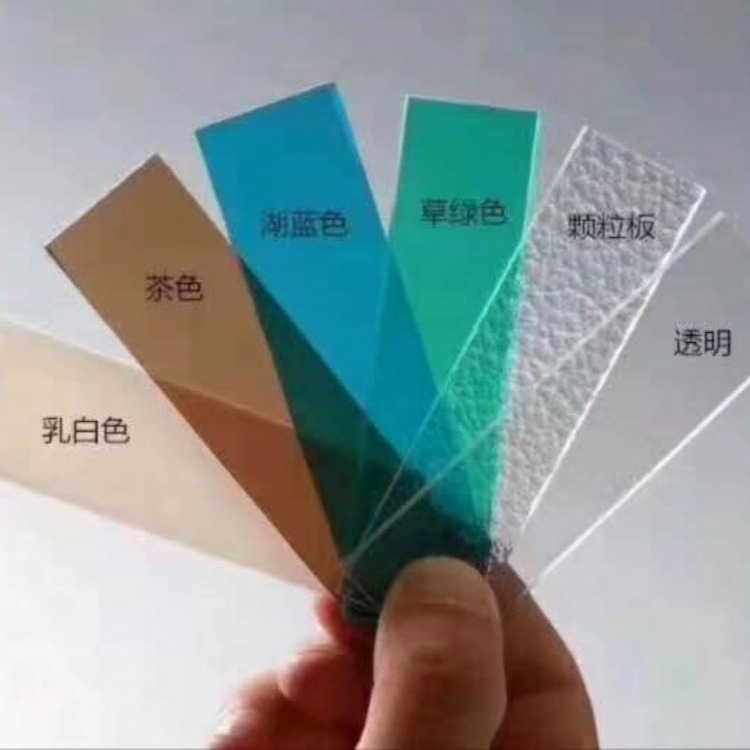

安博朗亚克力有机玻璃基本上涵盖了市场上所有的主流颜色,目前有近八十种颜色可供选择,且都适当备有库存,解决了客户订货时间和数量的限制,同时也可根据客户需要定做特殊颜色.颜色板搭配进口色膏,颜色鲜艳,色彩纯正,有极好的耐候性和可塑性.常用于制作LEO吸塑发光字、广告标识标牌等。