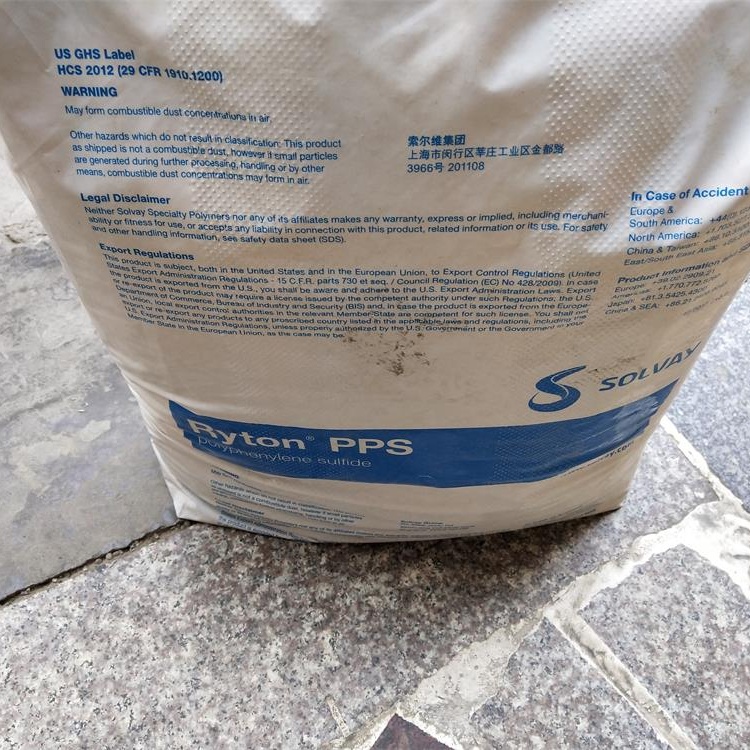

东莞市恒磊塑胶有限公司

PPS RYTON QC160P

Ryton? QC160P (pelletized) polyphenylene sulfide exhibits excellent thermal stability and chemical resistance and is suitable for thermoplastic extrusion processes.

Key Attributes: Chemical Resistant; Good Thermal Stability

Applications: Film; Stock Material for Machining

Information provided by Solvay Specialty Polymers.

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| Density | 1.34g/cc | 0.0484lb/in3 | ASTM D792 |

| Volatiles | 0.30 % | 0.30 % | |

| Water Absorption | 0.050 % @Time 86400 sec |

0.050 % @Time 24.0 hour |

ASTM D570 |

| Melt Flow | 45g/10 min @Load 5.00 kg, Temperature 316 °C |

45g/10 min @Load 11.0 lb, Temperature 601 °F |

Procedure B; ASTM D1238 |

| Ash | 0.30 % | 0.30 % | ISO 3451-1 |

| Mechanical Properties | Metric | English | Comments |

| Tensile Strength at Break | 75.0MPa | 10900psi | ISO 527-2 |

| Elongation at Break | 6.0 % | 6.0 % | ISO 527-2 |

| Tensile Modulus | 3.40GPa | 493ksi | ISO 527-2 |

| Flexural Strength | 130MPa | 18900psi | ISO 178 |

| Flexural Modulus | 3.40GPa | 493ksi | ISO 178 |

| Izod Impact, Notched | 0.530J/cm @Thickness 3.18 mm |

0.993ft-lb/in @Thickness 0.125 in |

ASTM D256 |

| Izod Impact, Notched (ISO) | 4.00kJ/m2 | 1.90ft-lb/in2 | Notch A; ISO 180 |

| Electrical Properties | Metric | English | Comments |

| Volume Resistivity | 1.00e 16ohm-cm | 1.00e 16ohm-cm | ASTM D257 |

| Surface Resistance | 1.00e 16ohm | 1.00e 16ohm | ASTM D257 |

| Dielectric Constant | 3.2 @Frequency 1.00e 6 Hz |

3.2 @Frequency 1.00e 6 Hz |

ASTM D150 |

| Dielectric Strength | 24.0kV/mm | 610kV/in | ASTM D149 |

| Dissipation Factor | 0.0020 @Frequency 1.00e 6 Hz |

0.0020 @Frequency 1.00e 6 Hz |

ASTM D150 |