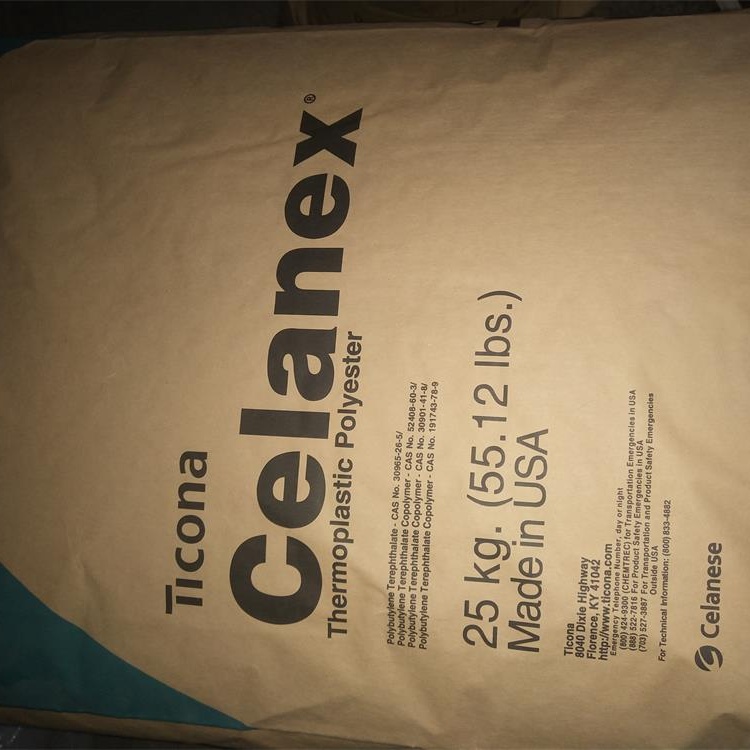

PBT CELANEX 3300LM

Celanex 3300LM is a 30% glass reinforced lasermarkable grade specially formulated to yield crisp marks when subjected to a Nd:YAG laser or equivalent operated at 1064nm or 532nm. Lasers operating in the UV region (355nm) may yield different results3300LM also offers a superior combination of mechanical, electrical, and thermal properties. This grade provides outstanding processability and good chemical resistance.

Information provided by Celanese

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| Specific Gravity | 1.53 g/cc | 1.53 g/cc | ASTM D792 |

| Density | 1.53 g/cc | 0.0553 lb/in3 | ISO 1183 |

| Moisture Absorption | 0.200 % | 0.200 % | 23°C/50%RH; ISO 62 |

| Linear Mold Shrinkage, Flow | 0.0020 - 0.0050 cm/cm | 0.0020 - 0.0050 in/in | ISO 294-4 |

| 0.0030 - 0.0050 cm/cm | 0.0030 - 0.0050 in/in | ASTM D955 | |

| Linear Mold Shrinkage, Transverse | 0.014 - 0.021 cm/cm | 0.014 - 0.021 in/in | ISO 294-4 |

| Melt Flow | 17 g/10 min @Load 2.16 kg, Temperature 250 °C |

17 g/10 min @Load 4.76 lb, Temperature 482 °F |

[cm3/10min]; ISO 1133 |

| Mechanical Properties | Metric | English | Comments |

| Hardness, Rockwell M | 90 | 90 | ISO 2039-2 |

| Tensile Strength at Break | 130 MPa | 18900 psi | 5mm/min; ISO 527-2/1A |

| 134 MPa | 19500 psi | ASTM D638 | |

| Elongation at Break | 2.0 % | 2.0 % | ASTM D638 |

| 2.5 % | 2.5 % | 5mm/min; ISO 527-2/1A | |

| Tensile Modulus | 9.20 GPa | 1330 ksi | 50mm/min; ISO 527-2/1A |

| Flexural Strength | 193 MPa | 28000 psi | ASTM D790 |

| 210 MPa | 30500 psi | ISO 178 | |

| Flexural Modulus | 8.27 GPa | 1200 ksi | ASTM D790 |

| 9.70 GPa | 1410 ksi | ISO 178 | |

| Izod Impact, Notched | 0.908 J/cm | 1.70 ft-lb/in | ASTM D256 |

| Izod Impact, Notched (ISO) | 7.50 kJ/m2 | 3.57 ft-lb/in2 | ISO 180/1A |

| Charpy Impact Unnotched | 4.60 J/cm2 | 21.9 ft-lb/in2 | ISO 179/1eU |

| 4.50 J/cm2 @Temperature -30.0 °C |

21.4 ft-lb/in2 @Temperature -22.0 °F |

ISO 179/1eU | |

PBT CELANEX 3300LM

PBT中文名称聚对苯二甲酸丁酯,简称饱和聚酯,系高结晶性热可塑性塑料。

优点:1、机械性质安定抗张强度与抗张模量和尼龙相似;2、摩擦系数小有自润性;

3、吸水率低;4、电气性质优良;5、尺寸安定性良好;6、耐药品性、耐油性极佳。

用途:1、电子电器:无熔线断电器、电磁开关、驰返变压器、家电把手、连接器、外壳等;

2、汽车:车门把手、保险杆、分电盘盖、挡泥板、导线护壳、轮圈盖等;

3、工业零件:OA风扇、键盘、钓具卷线器、零件、灯罩等。

特点:PBT为乳白色半透明到不透明、结晶型热塑性聚酯。具有高耐热性、韧性、耐疲劳性,自润滑、低摩擦系数,耐候性、吸水率低,仅为0.1%,在潮湿环境中仍保持各种物性(包括电性能),电绝缘性,但介电损耗大。耐热水、碱类、酸类、油类、但易受卤化烃侵蚀,耐水解性差,低温下可迅速结晶,成型性良好。PBT 结晶速度快,最适宜加工方法为注塑,其他方法还有挤出、吹塑、涂覆和各种二次加工成型,成型前需预干燥,水分含量要降至0.02%。PBT(增强、改性PBT)主要用于汽车、电子电器、工业机械和聚合物合金、共混工业。如作为汽车中的分配器、车体部件、点火器线圈骨架、绝缘盖、排气系统零部件、摩托车点火器、电子电器工业中如电视机的偏转线圈,显像管和电位器支架,伴音输出变压器骨架,适配器骨架,开关接插件、电风扇、电冰箱、洗衣机电机端盖、轴套.