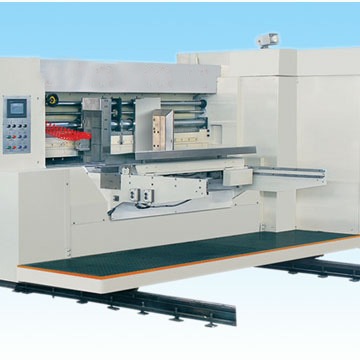

QY前缘送纸电脑全自动圆压圆模切机

文章来源: 发布时间:2015-04-11 11:21:26 阅读次数:846次

主要机构性能:

◎采用PLC程序控制,保护功能完善,控制可靠性高;

◎LCD触摸屏实现人机对话操作方便直观;

◎软辊自动修磨机构提高胶套重复使用率,可修磨3-4次;

◎限速度自动补偿确保每一批纸箱的模切尺寸完全一致;

◎模切辊为优持钢材质,壁厚30mm,平衡校正,镀硬铬;

◎墙板为优质铸铁材质,壁厚50mm,大型加工中心制作;

◎进口美国CUE聚胺脂胶垫,安装方便,模切1200万次;

◎机械式软辊左右横向移动40mm,胶垫磨损均匀;

◎六级精磨齿轮采用40cr材质,噪音低,使用寿命长;

◎模切辊汽缸式自动分离装置,减少胶套磨损。

◎采用世界先进的前缘送纸系统,送纸精度高,速度快,送

纸轮寿命长,送纸实现10000张/小时,精度±0.5mm;

◎风机风量可以任意调整,可满足送纸风量要求;

◎相位采用微电脑控制,可360°相位任意调整,快捷准

确;

◎前挡扳手动调整,侧挡板电脑调整;

Performance of the main mechanisms:

1.It adopts PLC controls , perfect protection function . Reliable control.

2.LCD touch screen can make the human and machine talk directly.

3.Soft roller repair structure , it can improve rubber using rate , it can repair 3-4times.

4.Compensate automatically with limited speed and ensure the size of die-cutting is consistent.

5.The die-cutting roller is alloy steel in high quality , wall thickness is 30mm , balanced

correction and hard chrome.

6.Wall plate is excellent cast iron , thickness is 50mm . It is made by large processing center.

7.The polyurethane rubber pad is from American CUE , install conveniently , it can die-cutting

12000000 times.

8.Soft roller can be moved right and left 40mm automatically , rubber wore is even.

9.Six grades is excellent grinding , it adopts 40Cr material .low noise and long using life.

10.Die-cutting roller is with auto separate device and reduce rubber wearing.

11.It adopts advanced leading edge system , high feeding precision , fast speed, feeding wheel

is using life , the speed can be up to 10000pcs/hour , precision is ±0.5mm.

12.The blowing rate can be controlled.

13.The phase is controlled by computer and 360°phase adjustment , fast and accurate.

14.Ahead guard is adjusted manually , side guard is adjusted by computer.

主要技术参数: