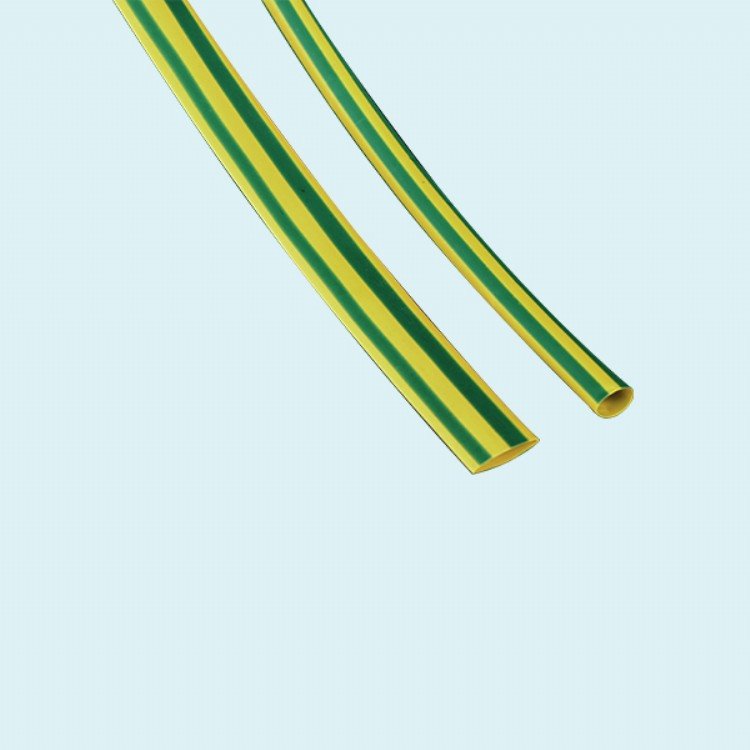

M-300 阻燃中壁护套管

产品简介

具有优异的阻燃、密封、绝缘、防潮、抗冲击及耐磨性能。广泛用于有阻燃要求的电缆终端或中间连接处的密封与绝缘防护以及其他需要机械防护、防腐、密封且有阻燃要求胡工作环境。

性能特点

阻燃、带胶、优异的机械保护性能、密封、防潮、防水

关键指标

收缩比率:3:1

收缩温度:120℃

使用温度:-55℃~ 110℃

标准颜色:黑色

性能指标

测试项目 |

测试方法 |

性能指标 |

外层性能 |

ASTM D 2671 |

≥14MPa |

拉伸强度 |

ASTM D 2671 |

≥12MPa |

老化后拉伸强度 (150℃,168hrs) |

ASTM D 2671 |

0~-10% |

纵向收缩率 |

ASTM D 2671 |

≥400% |

断裂伸长率 |

ASTM D 2671 |

≥300% |

老化后断裂伸长率(150℃,168hrs) |

IEC 243 |

≥18KV/mm |

击穿强度 |

ASTM D 792 |

1.05g/cm3 |

密度 |

IEC 93 |

≥1013Ω•cm |

体积电阻率 |

- |

60秒内自熄 |

阻燃性 |

||

热熔胶性能 |

||

吸水率 |

ISO 62 |

≤0.2% |

软化点 |

ASTM E 28 |

85 5℃ |

剥离强度(PE) |

DIN 30672 |

4N/cm |

抗茵性 |

ISO 746 |

通过 |

产品规格

尺寸(mm) |

供应尺寸(mm) |

回缩后尺寸(mm) |

管型 |

标准长度(mm) |

|

内径(最小值) |

内径(最大值) |

壁厚(最小值) |

|||

M-300 22/6 |

22 |

6 |

2.5 |

0 |

1000-1500 |

M-300 33/8 |

33 |

8 |

2.5 |

0 |

1000-1500 |

M-300 40/12 |

40 |

12 |

2.5 |

0 |

1000-1500 |

M-300 55/16 |

55 |

16 |

2.7 |

0 |

1000-1500 |

M-300 65/19 |

65 |

19 |

2.8 |

0 |

1000-1500 |

M-300 75/22 |

75 |

22 |

3.0 |

0 |

1000-1500 |

M-300 95/25 |

95 |

25 |

3.0 |

0 |

1000-1500 |

M-300 115/34 |

115 |

34 |

3.0 |

0 |

1000-1500 |

M-300 140/42 |

140 |

42 |

3.0 |

0 |

1000-1500 |

M-300 160/50 |

160 |

50 |

3.0 |

0 |

1000-1500 |

其他规格尺寸可定制。

M-300 Flame Retardant Wall Protecting Sleeve

Product Brief

As excellent flame retardant, sealing, insulation, moisture-proof, shock resistance and wear resistance. A widely used flame retardant requirement cable terminal or the middle connecting sealing and insulation protection at and other required mechanical protection, corrosion, sealing and flame retardant requirements work environment.

Performance characteristics

Flame retardant, adhesive, excellent mechanical performance, protection, moisture-proof, waterproof sealing.

Key indicators

Contraction ratio: 3:1

The shrinkage temperature: 120℃

The use of temperature: -55℃~ 110℃

Standard color: Black

Performance index

The test project |

Test method |

Performance index |

The outer performance |

ASTM D 2671 |

≥14MPa |

Tensile strength |

ASTM D 2671 |

≥12MPa |

The tensile strength after aging(150℃,168hrs) |

ASTM D 2671 |

0~-10% |

The longitudinal shrinkage rate |

ASTM D 2671 |

≥400% |

The elongation at break |

ASTM D 2671 |

≥300% |

Elongation after aging (150℃,168hrs) |

IEC 243 |

≥18KV/mm |

The breakdown strength |

ASTM D 792 |

1.05g/cm3 |

Density |

IEC 93 |

≥1013Ω•cm |

The volume resistivity |

- |

60 seconds self extinguishing |

Flame retardant |

||

The properties of the hot melt adhesive |

||

The rate of water absorption |

ISO 62 |

≤0.2% |

Softening point |

ASTM E 28 |

85 5℃ |

Peel strength (PE) |

DIN 30672 |

4N/cm |

Anti bacterial |

ISO 746 |

Pass |

Product specifications

Size(mm) |

Size (mm) |

After retraction of size (mm) |

Tube type |

Standard length(mm) |

|

Diameter (minimum) |

Diameter (maximum) |

Wall thickness (minimum) |

|||

M-300 22/6 |

22 |

6 |

2.5 |

0 |

1000-1500 |

M-300 33/8 |

33 |

8 |

2.5 |

0 |

1000-1500 |

M-300 40/12 |

40 |

12 |

2.5 |

0 |

1000-1500 |

M-300 55/16 |

55 |

16 |

2.7 |

0 |

1000-1500 |

M-300 65/19 |

65 |

19 |

2.8 |

0 |

1000-1500 |

M-300 75/22 |

75 |

22 |

3.0 |

0 |

1000-1500 |

M-300 95/25 |

95 |

25 |

3.0 |

0 |

1000-1500 |

M-300 115/34 |

115 |

34 |

3.0 |

0 |

1000-1500 |

M-300 140/42 |

140 |

42 |

3.0 |

0 |

1000-1500 |

M-300 160/50 |

160 |

50 |

3.0 |

0 |

1000-1500 |

Other sizes are available upon request.