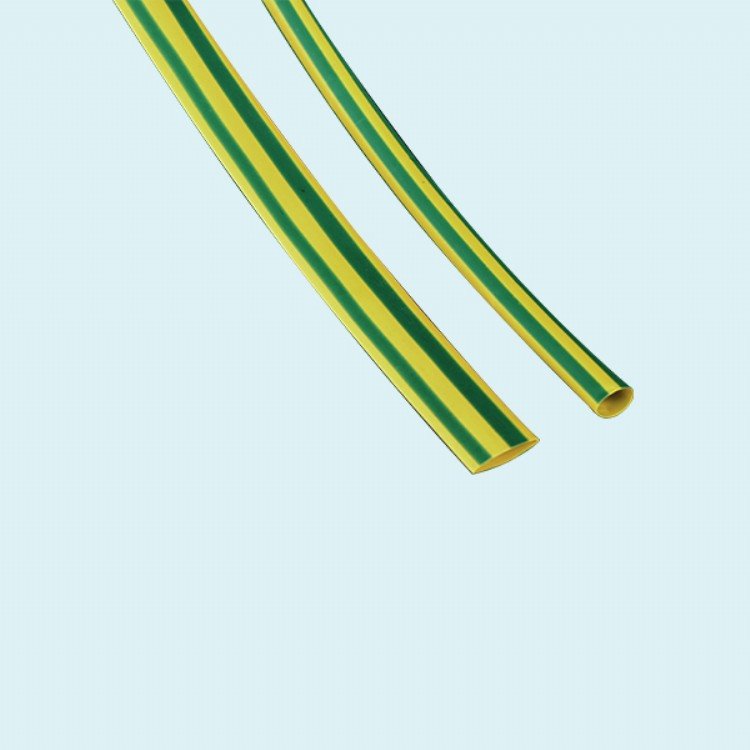

DW125 柔软高倍双壁热收缩套管

应用

由聚烯烃和热熔胶共挤制造而成,用于需要密封防水防潮的电线电缆、配线和连接器的绝缘保护,可以很好地应用于电子电器、汽车和通讯等很多行业中。

特性

优异的热熔胶和高的收缩比提供了优异的密封

用于电子连接部分应用的密封和绝缘保护

不需要移开连接器就可以方便修补损伤的绝缘层

可选用EVA热熔胶或聚酰胺(PA)热熔胶

高收缩比3:1、4:1可用作非规则形状物件的绝缘和密封保护

柔软、阻燃

符合ROHS、REACH等环保规范

颜色

标准颜色:黑色

其他颜色可订制

操作温度范围

连续使用温度范围:-55℃~125℃

最低起始收缩温度:80℃

最低完全收缩温度:110℃

符合标准

SAE AMS-DTL-23053/4

UL224 E360866 125℃ 600V

性能指标

性能 |

指标要求 |

测试方法 |

典型值 |

纵向收缩率 |

≤10% |

ASTM D 2671 |

≤5% |

抗张强度 |

10.3MPa min |

ASTM D 638 |

≥12MPa |

断裂伸长率 |

200% min |

ASTM D 638 |

≥400% |

老化后抗张强度 (热老化158℃,168小时) |

初始值的70%以上 |

ASTM D 638 |

≥90% |

老化后断裂伸长率(158℃,168hrs) |

100% min |

ASTM D 638 |

≥300% |

热冲击

|

无裂纹 |

ASTM D 2671 |

无裂纹 |

低温柔软性 (-55℃,4小时) |

无裂纹 |

ASTM D 2671 |

无裂纹 |

绝缘耐压和击穿 |

2500V,60sec,不击穿 |

ASTM D 2671 |

不击穿 |

体积电阻率 |

1014Ω•cm min |

ASTM D 638 |

≥1014Ω•cm |

铜腐性 |

无腐蚀 |

ASTM D 2671 |

无腐蚀 |

阻燃性 |

ALL TUBING FLAME TEST |

UL224 |

通过 |

规格尺寸

规格 |

收缩前(mm) |

收缩后(mm) |

标准包装(m/条或m/卷) |

||

内径(min) |

内径(max) |

壁厚 |

胶厚 |

||

3:1(inch,mm) |

|||||

1/8(3/1) |

3.0 |

1.0 |

1.00+0.28 |

0.50 |

1.22/200 |

3/6(4.8/1.6) |

4.8 |

1.6 |

1.00+0.28 |

0.50 |

1.22/100 |

1/4(6/2) |

6.0 |

2.0 |

1.00+0.28 |

0.50 |

1.22/100 |

3/8(9/3) |

9.0 |

3.0 |

1.40+0.28 |

0.60 |

1.22/50 |

1/2(12/4) |

12.0 |

4.0 |

1.78+0.38 |

0.76 |

1.22/25 |

3/4(18/6) |

18.0 |

6.0 |

2.25+0.55 |

0.76 |

1.22/25 |

1(24/8) |

24.0 |

8.0 |

2.54+0.55 |

1.02 |

1.22/25 |

11/2(39/13) |

39.0 |

13.0 |

2.54+0.55 |

1.02 |

1.22/25 |

4:1(mm) |

|||||

4/1 |

4.0 |

1.0 |

1.00+0.28 |

0.50 |

1.22/100 |

8/2 |

8.0 |

2.0 |

1.00+0.28 |

0.50 |

1.22/50 |

12/3 |

12.0 |

3.0 |

1.40+0.28 |

0.60 |

1.22/25 |

16/4 |

16.0 |

4.0 |

1.78+0.38 |

0.76 |

1.22/25 |

24/6 |

24.0 |

6.0 |

2.25+0.55 |

0.76 |

1.22/25 |

32/8 |

32.0 |

8.0 |

2.54+0.55 |

1.02 |

1.22/25 |

52/13 |

52.0 |

13.0 |

2.54+0.55 |

1.02 |

1.22 |

壁厚包含胶厚

其他规格尺寸可定制

DW125 Soft And High Times Double Wall Heat Shrinkable Sleeve

Application

Dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent polyolefin compounds and hot-melt adhesive. It is used for water-proofing and insulation protection of wire and cable and wire harnesses, and connector-to-cable transitions. It is typically used in the insulation and sealing of electrical and electronic components, automotive and communication industry.

Characteristics

Good hot-melt adhesive and high expansion ratio to provide good sealing protection.

Environmental sealing and protection of electrical applications.

Conveniently repair most damaged cable jackets without removing connectors.

EVA hot melt adhesive or PA adhesive are available.

High Shrink ratio 3:1 and 4:1 allows for insulation and sealing of irregular shapes.

Flexible, flame retardant

ROHS and REACH compliant

Color

Standard color: Black

Other colors are available upon request.

Operating Temperature Range

Operating temperature: -55℃~125℃

Minimum shrink temperature: 80℃

Minimum fully recovery temperature: 110℃

Approvals

SAE AMS-DTL-23053/4

UL224 E360866 125℃ 600V

Property

Property |

Requirement |

Test method |

Typical data |

Longitudinal shrinkage |

≤10% |

ASTM D 2671 |

≤5% |

Tensile strength |

10.3MPa min |

ASTM D 638 |

≥12MPa |

Elongation at break |

200% min |

ASTM D 638 |

≥400% |

Tensile strength after aging (158℃,168hrs) |

70% of original

|

ASTM D 638 |

≥90% |

Elongation after aging (158℃,168hrs) |

100% min |

ASTM D 638 |

≥300% |

Heat shock

|

No crack |

ASTM D 2671 |

No crack |

Low-temperature flexibility(-55℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

Dielectric voltage withstand |

2500V,60sec,no breakdown |

ASTM D 2671 |

No breakdown |

Volume resistivity |

1014Ω•cm min |

ASTM D 638 |

≥1014Ω•cm |

Copper corrosion |

No corrosion |

ASTM D 2671 |

No corrosion |

Flammability |

ALL TUBING FLAME TEST |

UL224 |

Pass |

Sizes

Size

|

As supplied (mm) |

After recovered(mm) |

Standard packing (m/pc,m/roll) |

||

Inside diameter (min) |

Inside diameter (max) |

Wall thickness |

Adhesive thickness (nominal) |

||

3:1(inch,mm) |

|||||

1/8(3/1) |

3.0 |

1.0 |

1.00+0.28 |

0.50 |

1.22/200 |

3/6(4.8/1.6) |

4.8 |

1.6 |

1.00+0.28 |

0.50 |

1.22/100 |

1/4(6/2) |

6.0 |

2.0 |

1.00+0.28 |

0.50 |

1.22/100 |

3/8(9/3) |

9.0 |

3.0 |

1.40+0.28 |

0.60 |

1.22/50 |

1/2(12/4) |

12.0 |

4.0 |

1.78+0.38 |

0.76 |

1.22/25 |

3/4(18/6) |

18.0 |

6.0 |

2.25+0.55 |

0.76 |

1.22/25 |

1(24/8) |

24.0 |

8.0 |

2.54+0.55 |

1.02 |

1.22/25 |

11/2(39/13) |

39.0 |

13.0 |

2.54+0.55 |

1.02 |

1.22/25 |

4:1(mm) |

|||||

4/1 |

4.0 |

1.0 |

1.00+0.28 |

0.50 |

1.22/100 |

8/2 |

8.0 |

2.0 |

1.00+0.28 |

0.50 |

1.22/50 |

12/3 |

12.0 |

3.0 |

1.40+0.28 |

0.60 |

1.22/25 |

16/4 |

16.0 |

4.0 |

1.78+0.38 |

0.76 |

1.22/25 |

24/6 |

24.0 |

6.0 |

2.25+0.55 |

0.76 |

1.22/25 |

32/8 |

32.0 |

8.0 |

2.54+0.55 |

1.02 |

1.22/25 |

52/13 |

52.0 |

13.0 |

2.54+0.55 |

1.02 |

1.22 |

Wall thickness includes adhesive thickness.

Other sizes are available upon request.