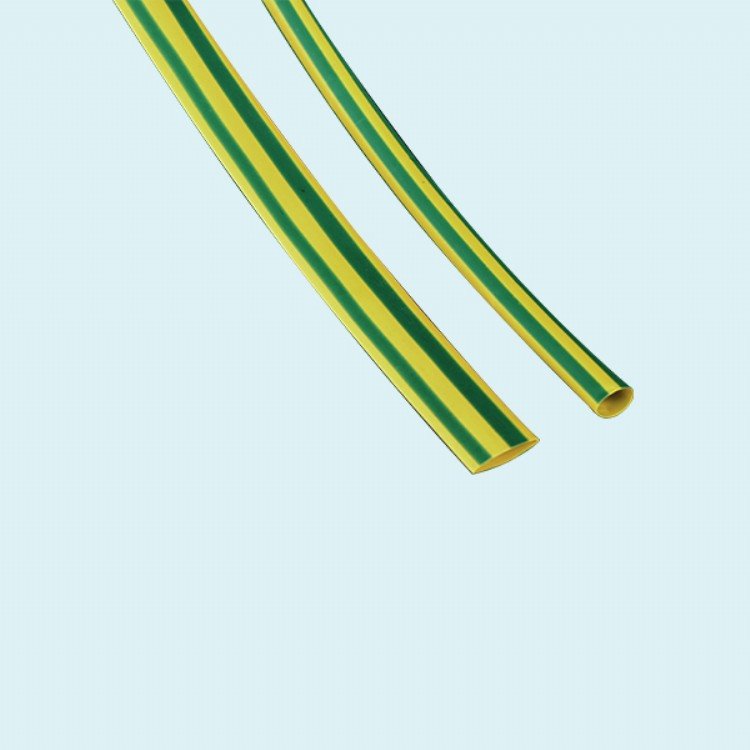

V200 军标级耐温200℃氯橡胶热缩管

应用

由辐照交联优质氟橡胶制成,适用于需要耐高温、耐油、耐化学溶剂的环境,具有优异的耐高温、耐化学腐蚀和耐溶剂性能,防止线束、线缆或被覆元器件在高温或特别苛刻的环境中免受损伤。

特性

收缩比:2:1

耐温200℃,优异的耐高低温性能

优异的耐磨、耐溶剂及耐化学腐蚀性能

很柔软、优异的阻燃性

符合ROHS、REACH等环保规范

颜色

标准颜色:黑色

操作温度范围

连续使用温度范围:-65℃~200℃

最低起始收缩温度:150℃

最低完全收缩温度:175℃

符合标准

SAE AMS-DTL-23053/13

性能指标

性能 |

指标要求 |

测试方法 |

典型值 |

纵向收缩率 |

≤10% |

ASTM D 2671 |

≤5% |

抗张强度 |

8.2MPa min |

ASTM D 638 |

≥12MPa |

断裂伸长率 |

250% min |

ASTM D 638 |

≥400% |

老化后断裂伸长率(250℃,168小时) |

200% min |

ASTM D 638 |

≥300% |

热冲击 (300℃,4小时) |

无裂纹 |

ASTM D 2671 |

无裂纹 |

低温柔软性 (-55℃,4小时) |

无裂纹 |

ASTM D 2671 |

无裂纹 |

绝缘耐压和击穿 |

2500V,60sec,不击穿 |

ASTM D 2671 |

通过 |

击穿强度 |

7.9 KV/mm min |

ASTM D 2671 |

≥12KV/mm |

体积电阻率 |

109Ω•cm min |

ASTM D 876 |

≥109Ω•cm |

腐蚀性 |

无腐蚀 |

ASTM D 2671 |

通过 |

阻燃性 |

15分钟内自熄 |

ASTM D 2671 |

通过 |

耐液性(23℃,24hrs) |

|||

抗张强度 |

8.2MPa min |

ASTM D 638 |

≥12MPa |

断裂伸长率 |

250% min |

ASTM D 638 |

≥400% |

规格尺寸

规格 |

收缩前(mm) |

收缩后(mm) |

标准包装 (m/卷) |

||

英制 |

公制 |

内径(min) |

内径(max) |

壁厚 |

|

3/32 |

Ф2.4 |

2.4 |

1.2 |

0.51 0.08 |

200 |

1/8 |

Ф3.2 |

3.2 |

1.6 |

0.76 0.13 |

100 |

3/16 |

Ф4.8 |

4.8 |

2.4 |

0.89 0.18 |

50 |

1/4 |

Ф6.4 |

6.4 |

3.2 |

0.89 0.18 |

50 |

3/8 |

Ф9.5 |

9.5 |

4.8 |

0.89 0.18 |

50 |

1/2 |

Ф12.7 |

12.7 |

6.4 |

0.89 0.18 |

50 |

3/4 |

Ф19.1 |

19.1 |

9.5 |

1.07 0.21 |

30 |

1 |

Ф25.4 |

25.4 |

12.7 |

1.25 0.30 |

30 |

11/2 |

Ф38.1 |

38.1 |

19.1 |

1.40 0.38 |

30 |

2 |

Ф50.8 |

50.8 |

25.4 |

1.65 0.43 |

30 |

其他规格尺寸可定制

V200 200℃ High Temperature Resistance Fluororubber Tubing

Application

Made from a cross-linked fluoroelastomer compound with superior impact, abrasion and cut through resistance. Especially used for applications requiring high resistance to corrosive fluids, fuels, lubricants, acids and solvents to prevent wire harnesses, cables and appliances at elevated temperatures.

Characteristics

Shrink ratio: 2:1

High temperature resistant up to 200℃, excellent high and low temperature resistance

Excellent abrasion resistance and resistance to oil, diesel and hydraulic fluids.

Very flexible, highly flame-retardant

ROHS and REACH compliant

Color

Color Standard color: Black

Operating Temperature Range

Operating temperature: -65℃~200℃

Minimum shrink temperature: 150℃

Minimum fully recovery temperature: 175℃

Approvals

SAE AMS-DTL-23053/13

Property

Property |

Requirement |

Test method |

Typical data |

Longitudinal shrinkage |

≤10% |

ASTM D 2671 |

≤5% |

Tensile strength |

8.2MPa min |

ASTM D 638 |

≥12MPa |

Elongation at break |

250% min |

ASTM D 638 |

≥400% |

Elongation after aging (250℃,168hrs) |

200% min |

ASTM D 638 |

≥300% |

Heat shock (300℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

Low-temperature flexibility(-55℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

Dielectric voltage withstand |

2500V,60sec,no breakdown |

ASTM D 2671 |

Pass |

Dielectric strength |

7.9 KV/mm min |

ASTM D 2671 |

≥12KV/mm |

Volume resistivity |

109Ω•cm min |

ASTM D 876 |

≥109Ω•cm |

Copper corrosion |

No corrosion |

ASTM D 2671 |

Pass |

Flammability |

Self-extinguishing within 15s |

ASTM D 2671 |

Pass |

Fluids resistance(23℃,24hrs) |

|||

Tensile strength |

8.2MPa min |

ASTM D 638 |

≥12MPa |

Elongation at break |

250% min |

ASTM D 638 |

≥400% |

Sizes

Size |

As supplied (mm) |

After recovered(mm) |

Standard packing (m/roll) |

||

inch |

mm |

Inside diameter(min) |

Inside diameter max |

Wall thickness |

|

3/32 |

Ф2.4 |

2.4 |

1.2 |

0.51 0.08 |

200 |

1/8 |

Ф3.2 |

3.2 |

1.6 |

0.76 0.13 |

100 |

3/16 |

Ф4.8 |

4.8 |

2.4 |

0.89 0.18 |

50 |

1/4 |

Ф6.4 |

6.4 |

3.2 |

0.89 0.18 |

50 |

3/8 |

Ф9.5 |

9.5 |

4.8 |

0.89 0.18 |

50 |

1/2 |

Ф12.7 |

12.7 |

6.4 |

0.89 0.18 |

50 |

3/4 |

Ф19.1 |

19.1 |

9.5 |

1.07 0.21 |

30 |

1 |

Ф25.4 |

25.4 |

12.7 |

1.25 0.30 |

30 |

11/2 |

Ф38.1 |

38.1 |

19.1 |

1.40 0.38 |

30 |

2 |

Ф50.8 |

50.8 |

25.4 |

1.65 0.43 |

30 |

Other sizes are available upon request.