CX100 磁性热收缩套管

应用

由辐照交联特种磁性聚烯烃制成,电磁兼容性好、抗电磁干扰性好,能大大提高电子元件的电磁性能及其稳定性。可广泛应用于电子元器件行业,如电感、电容等,起到代替电感线圈外用磁罩、提升电感值、电磁兼容性(EMC)等作用;还可以用于PC电源、电容、数据线等需要电磁屏蔽的电子电路中,起电磁屏蔽作用。

特性

收缩比 2:1

优异的电磁兼容性(EMC)及抗电磁干扰性(EMI)

性能稳定,安装简单,收缩均匀

符合RoHS、REACH环保规范

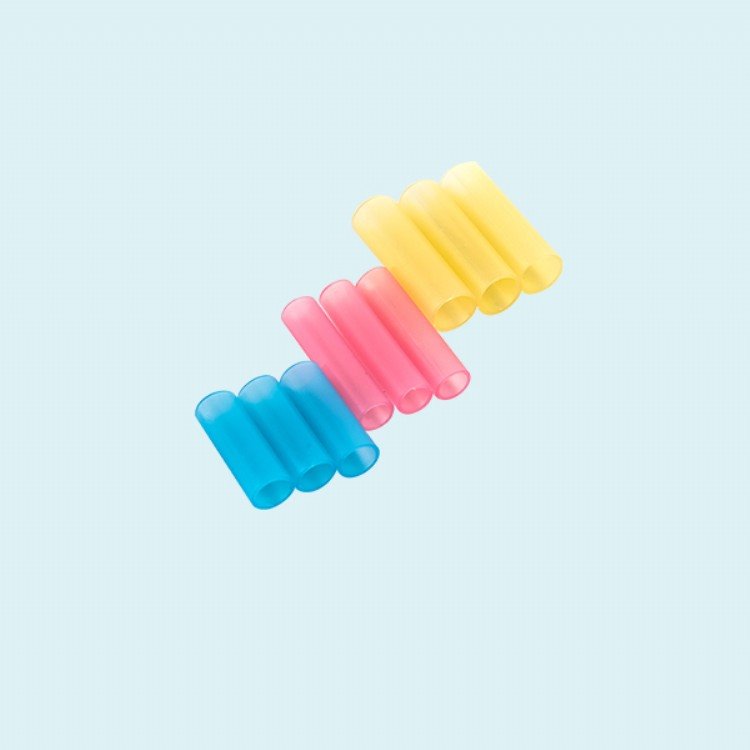

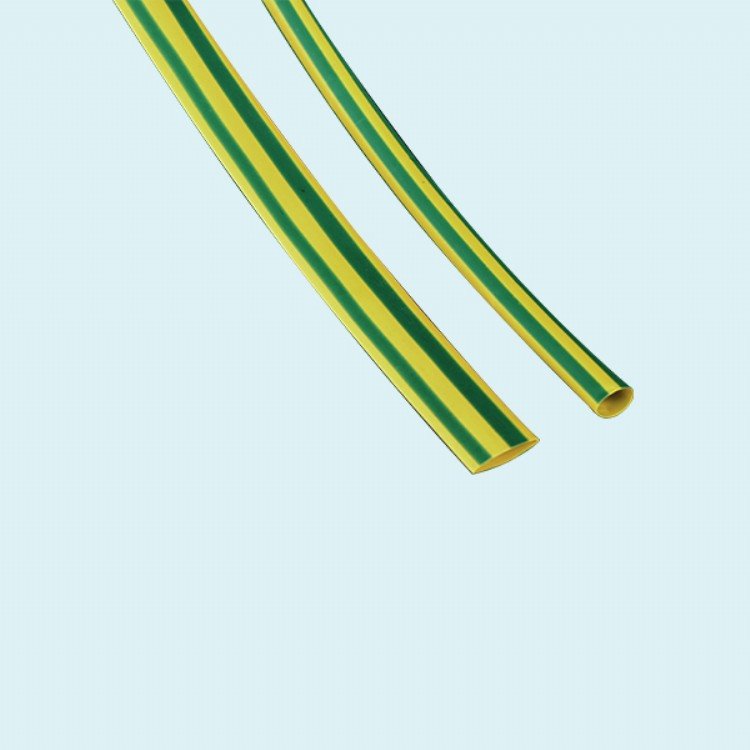

颜色

标准颜色:黑色

操作温度范围

连续使用温度:-55℃~125℃

最低起始收缩温度:60℃

最低完全收缩温度:110℃

性能指标

性能 |

指标要求 |

测试方法 |

典型值 |

纵向收缩率 |

≤10% |

ASTM D 2671 |

≤5% |

抗张强度 |

11.7MPa min |

ASTM D 638 |

≥12MPa |

断裂伸长率 |

300% min |

ASTM D 638 |

≥400% |

绝缘耐压和击穿 |

1500V,60sec,不击穿 |

ASTM D 2671 |

不击穿 |

体积电阻率 |

1014Ω•cm min |

ASTM D 876 |

≥1012Ω•cm |

工作频率 |

1K~500KHz |

||

电感上升幅度 |

10%~25% |

规格尺寸

规格 |

收缩前(mm) |

收缩后(mm) |

标准包装 (m/卷) |

||

内径(min) |

壁厚 |

内径(max) |

壁厚 |

||

Ф3 |

3.5 0.3 |

0.25 0.05 |

1.5 |

0.45 0.10 |

200 |

Ф4 |

4.5 0.3 |

0.25 0.05 |

2.0 |

0.45 0.10 |

100 |

Ф4.5 |

5.0 0.3 |

0.25 0.05 |

2.3 |

0.50 0.10 |

100 |

Ф5 |

5.5 0.4 |

0.28 0.06 |

2.5 |

0.56 0.10 |

100 |

Ф6 |

6.5 0.4 |

0.28 0.06 |

3.0 |

0.56 0.10 |

100 |

Ф7 |

7.5 0.4 |

0.28 0.06 |

3.5 |

0.56 0.10 |

100 |

Ф8 |

8.5 0.4 |

0.28 0.06 |

4.0 |

0.60 0.10 |

100 |

Ф9 |

9.5 0.4 |

0.30 0.08 |

4.5 |

0.60 0.10 |

100 |

Ф10 |

10.5 0.4 |

0.30 0.08 |

5.0 |

0.60 0.10 |

100 |

Ф11 |

11.5 0.5 |

0.30 0.08 |

5.0 |

0.60 0.10 |

100 |

Ф12 |

12.5 0.5 |

0.30 0.08 |

6.0 |

0.60 0.10 |

100 |

Ф13 |

13.5 0.5 |

0.35 0.10 |

6.5 |

0.65 0.10 |

100 |

Ф14 |

14.5 0.5 |

0.35 0.10 |

7.0 |

0.65 0.10 |

100 |

Ф15 |

15.5 0.5 |

0.35 0.10 |

7.5 |

0.68 0.10 |

100 |

其他规格尺寸可定制

CX100 Magnetic Heat-shrinkable Tubing

Application

It is made of special irradiation cross-linked magnetic polyolefin compounds with good EMC and EMI and properties to improve EMC properties of electronic appliances. It can be widely used in electronic appliance fields, i.e. Inductance, capacitance, to alternate mutual-induction protector of electric induction coil to increase inductance and EMC. It is also used for electromagnetic shield in electronic circuits of PC power, capacitance and data wires.

Characteristics

Shrink ratio: 2:1

Excellent EMC and EMI properties

Stable properties, easy installing, good shrink property.

ROHS and RAECH compliant.

Color

Standard color: black

Operating Temperature Range

Operating temperature: -55℃~125℃

Minimum shrink temperature: 60℃

Minimum fully recovery temperature: 110℃

Property

Property |

Requirement |

Test method |

Typical data |

Longitudinal shrinkage |

≤10% |

ASTM D 2671 |

≤5% |

Tensile strength |

11.7MPa min |

ASTM D 638 |

≥12MPa |

Elongation at break |

300% min |

ASTM D 638 |

≥400% |

Dielectric voltage withstand |

1500V,60sec,no breakdown |

ASTM D 2671 |

No breakdown |

Volume resistivity |

1014Ω•cm min |

ASTM D 876 |

≥1012Ω•cm |

Operating frequency |

1K~500KHz |

||

Inductance increase |

10%~25% |

Sizes

size |

As supplied(mm) |

After recovered(mm) |

Standard packing (m/roll) |

||

Inside diameter(min) |

Wall thickness |

Inside diameter(max) |

Wall thickness |

||

Ф3 |

3.5 0.3 |

0.25 0.05 |

1.5 |

0.45 0.10 |

200 |

Ф4 |

4.5 0.3 |

0.25 0.05 |

2.0 |

0.45 0.10 |

100 |

Ф4.5 |

5.0 0.3 |

0.25 0.05 |

2.3 |

0.50 0.10 |

100 |

Ф5 |

5.5 0.4 |

0.28 0.06 |

2.5 |

0.56 0.10 |

100 |

Ф6 |

6.5 0.4 |

0.28 0.06 |

3.0 |

0.56 0.10 |

100 |

Ф7 |

7.5 0.4 |

0.28 0.06 |

3.5 |

0.56 0.10 |

100 |

Ф8 |

8.5 0.4 |

0.28 0.06 |

4.0 |

0.60 0.10 |

100 |

Ф9 |

9.5 0.4 |

0.30 0.08 |

4.5 |

0.60 0.10 |

100 |

Ф10 |

10.5 0.4 |

0.30 0.08 |

5.0 |

0.60 0.10 |

100 |

Ф11 |

11.5 0.5 |

0.30 0.08 |

5.0 |

0.60 0.10 |

100 |

Ф12 |

12.5 0.5 |

0.30 0.08 |

6.0 |

0.60 0.10 |

100 |

Ф13 |

13.5 0.5 |

0.35 0.10 |

6.5 |

0.65 0.10 |

100 |

Ф14 |

14.5 0.5 |

0.35 0.10 |

7.0 |

0.65 0.10 |

100 |

Ф15 |

15.5 0.5 |

0.35 0.10 |

7.5 |

0.68 0.10 |

100 |

Other sizes are available upon request.