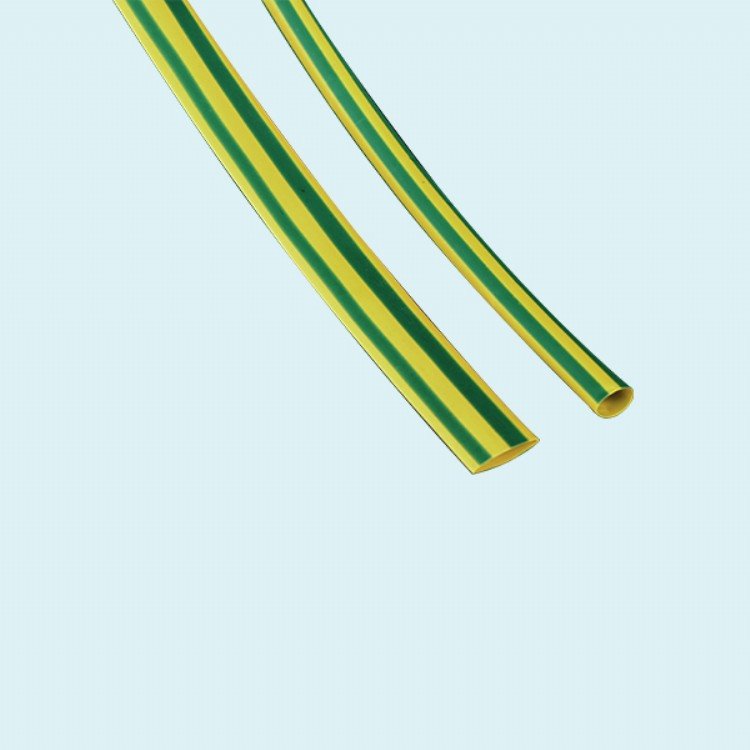

KY175 耐高温175℃ KYNAR热收缩套管

应用

由辐照交联特种含氟聚合物PVDF制成,具有优异的耐化学腐蚀和耐溶剂性能,是一种坚固、半硬、薄壁的热缩管,特别适用于需要耐高温和需要抗磨损对机械性能要求较高的环境,如航空航天、雷达、机车等线缆连接处和零部件的绝缘保护。用于连接处的绝缘保护和应力解除及被覆元件的区分识别,也可用于线缆标识的保护。

特性

收缩比:2:1

半硬,薄壁绝缘

优异的阻燃性

耐高温175℃

韧性好,优异的耐磨性能和耐化学腐蚀性能

符合ROHS、REACH等环保规范

颜色

标准颜色:黑色

其他颜色可定制

操作温度范围

连续使用温度范围:-55℃~175℃

最低起始收缩温度:155℃

最低完全收缩温度:175℃

符合标准

SAE AMS-DTL-23053/13

UL224 E360866 600V VW-1

性能指标

性能 |

指标要求 |

测试方法 |

典型值 |

纵向收缩率 |

≤10% |

ASTM D 2671 |

≤5% |

抗张强度 |

34.5MPa min |

ASTM D 638 |

≥35MPa |

断裂伸长率 |

150% min |

ASTM D 638 |

≥300% |

老化后断裂伸长率 (热老化250℃,168小时) |

175% min |

ASTM D 638 |

≥200% |

热冲击(300℃,4小时)

|

无裂纹 |

ASTM D 2671 |

无裂纹 |

低温柔软性 (-55℃,4小时) |

无裂纹 |

ASTM D 2671 |

无裂纹 |

绝缘耐压和击穿 |

2000V,60sec,不击穿 |

ASTM D 2671 |

不击穿 |

体积电阻率 |

1013Ω•cm min |

ASTM D 876 |

≥1013Ω•cm |

腐蚀性 |

无腐蚀 |

ASTM D 2671 |

无腐蚀 |

阻燃性 |

VW-1 |

UL 224 |

通过 |

规格尺寸

规格 |

收缩前(mm) |

收缩后(mm) |

标准包装 (m/条或m/卷) |

||

英制 |

公制 |

内径(min) |

内径(max) |

壁厚 |

|

3/64 |

Ф1.2 |

1.2 |

0.6 |

0.25 0.05 |

1.2/200 |

1/16 |

Ф1.6 |

1.6 |

0.8 |

0.25 0.05 |

1.2/200 |

3/32 |

Ф2.4 |

2.4 |

1.2 |

0.25 0.05 |

1.2/200 |

1/8 |

Ф3.2 |

3.2 |

1.6 |

0.25 0.05 |

1.2/200 |

3/16 |

Ф4.8 |

4.8 |

2.4 |

0.25 0.05 |

1.2/100 |

1/4 |

Ф6.4 |

6.4 |

3.2 |

0.30 0.08 |

1.2/100 |

3/8 |

Ф9.5 |

9.5 |

4.8 |

0.30 0.08 |

1.2/100 |

1/2 |

Ф12.7 |

12.7 |

6.4 |

0.30 0.08 |

1.2/100 |

3/4 |

Ф19.1 |

19.1 |

9.5 |

0.43 0.08 |

1.2/50 |

1 |

Ф25.4 |

25.4 |

12.7 |

0.48 0.08 |

1.2/50 |

11/2 |

Ф38.1 |

38.1 |

19.1 |

0.51 0.08 |

1.2 |

2 |

Ф50.8 |

50.8 |

25.4 |

0.58 0.08 |

1.2 |

其他规格尺寸可定制

KY175 175℃High-Temperature KYNAR Heat Shrinkable Tubing

Application

KY175 is made of special irradiation cross-linked fluoropolymer PVDF with outstanding chemical and solvent resistance and high-temperature performance. It is tough, semi-rigid, very thin wall especially suitable for applications requiring high-temperature performance, outstanding abrasion resistance and cut-through resistance, or superior chemical and solvent properties. It is also used for insulation and strain relief of soldered joints, identification and inspection of covered components.

Characteristics

Shrink ratio: 2:1

Semi-rigid, very thin wall insulation

Excellent flammability

High temperature resistant to 175℃

Good toughness, excellent abrasion resistance, physical and chemical properties.

ROHS and REACH compliant

Operating Temperature Range

Operating temperature: -55℃~175℃

Minimum shrink temperature: 155℃

Minimum fully recovery temperature: 175℃

Approvals

SAE AMS-DTL-23053/8

UL224 E360886 150℃ 600V VW-1

Property

Property |

Requirement |

Test method |

Typical data |

Longitudinal shrinkage |

≤10% |

ASTM D 2671 |

≤5% |

Tensile strength |

34.5MPa min |

ASTM D 638 |

≥35MPa |

Elongation at break |

150% min |

ASTM D 638 |

≥300% |

Elongation after aging (250℃,168hrs) |

175% min |

ASTM D 638 |

≥200% |

Heat shock (300℃,4hrs)

|

No crack |

ASTM D 2671 |

No crack |

Low-temperature flexibility(-55℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

Dielectric voltage withstand |

2000V,60sec,no breakdown |

ASTM D 2671 |

No breakdown |

Volume resistivity |

1013Ω•cm min |

ASTM D 876 |

≥1013Ω•cm |

Corrosion |

No corrosion |

ASTM D 2671 |

No corrosion |

Flammability |

VW-1 |

UL 224 |

Pass |

Sizes

size |

As supplied(mm) |

After recovered(mm) |

Standard packing (m/pc, m/roll) |

||

inch |

mm |

Inside diameter(min) |

Inside diameter(max) |

Wall thickness |

|

3/64 |

Ф1.2 |

1.2 |

0.6 |

0.25 0.05 |

1.2/200 |

1/16 |

Ф1.6 |

1.6 |

0.8 |

0.25 0.05 |

1.2/200 |

3/32 |

Ф2.4 |

2.4 |

1.2 |

0.25 0.05 |

1.2/200 |

1/8 |

Ф3.2 |

3.2 |

1.6 |

0.25 0.05 |

1.2/200 |

3/16 |

Ф4.8 |

4.8 |

2.4 |

0.25 0.05 |

1.2/100 |

1/4 |

Ф6.4 |

6.4 |

3.2 |

0.30 0.08 |

1.2/100 |

3/8 |

Ф9.5 |

9.5 |

4.8 |

0.30 0.08 |

1.2/100 |

1/2 |

Ф12.7 |

12.7 |

6.4 |

0.30 0.08 |

1.2/100 |

3/4 |

Ф19.1 |

19.1 |

9.5 |

0.43 0.08 |

1.2/50 |

1 |

Ф25.4 |

25.4 |

12.7 |

0.48 0.08 |

1.2/50 |

11/2 |

Ф38.1 |

38.1 |

19.1 |

0.51 0.08 |

1.2 |

2 |

Ф50.8 |

50.8 |

25.4 |

0.58 0.08 |

1.2 |

Other sizes are available upon request.