东莞市屹立塑胶有限公司

Cycoloy®聚碳酸酯/丙烯腈-丁二烯-苯乙烯共聚物(ABS)高影响非晶态热塑性塑料共混结合低温延性易于加工。具有优良的耐冲击性、耐热性、和突出的美学、Cycoloy树脂共混物可以定制以满足特定的性能要求,帮助平衡性能、成本和成型性.cycoloy树脂共混物提供优良的设计方案,在外观和耐久性是很重要的。

Cycoloy FR树脂聚碳酸酯/丙烯腈-丁二烯-苯乙烯(ABS)合金设计的阻燃应用符合UL和其他适用的标准。大多数这些材料是阻燃的标准,而不使用溴或氯的阻燃剂。这些树脂的测试按照UL94标准,从V2 V0等级,以及5VA,5VB等级。

这个组合是一个无定形的家庭的PC/ABS树脂树脂,是优秀的医疗保健市场的候选人。这些树脂是专为满足OEM的需求,制定控制生物相容性。可在广泛的不透明的颜色。

CYCOLOY PC/ABS Visualfx树脂成型™提供的效果,可以消除需要修改后成型,同时仍然提供冲击和加工优势,Cycoloy是众所周知的。这可以提供更清洁和更具活力的部分美学,可以持续,只要一部分持续。Visualfx包括火花和瓷的影响以及一些金属和天然材料的影响。可在各种颜色和基础树脂。

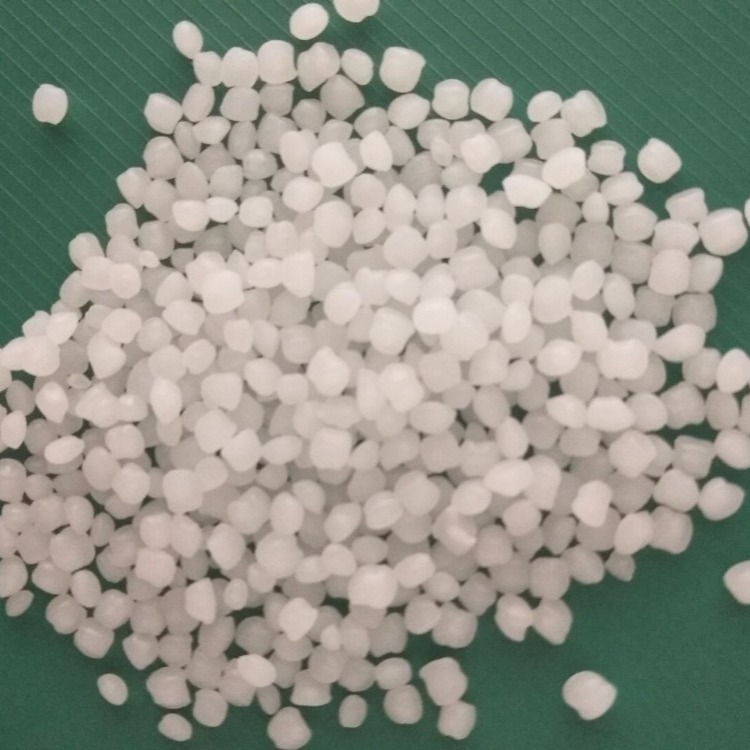

PC/ABS/沙伯基础(南沙)/CX7240-701:

①级别:注塑级

②特性:可注射模塑的非氯化溴化阻燃体系。薄壁FR和优异的冲击/流量平衡使得它非常适合薄壁应用。

| TYPICAL PROPERTIES (1) | ||||

| MECHANICAL | Value | Unit | Standard | |

| Tensile Stress, yld, Type I, 50 mm/min | 660 | kgf/cm2 | ASTM D 638 | |

| Tensile Stress, brk, Type I, 50 mm/min | 590 | kgf/cm2 | ASTM D 638 | |

| Tensile Strain, yld, Type I, 50 mm/min | 4.1 | % | ASTM D 638 | |

| Tensile Strain, brk, Type I, 50 mm/min | 100 | % | ASTM D 638 | |

| Tensile Modulus, 5 mm/min | 26500 | kgf/cm2 | ASTM D 638 | |

| Flexural Stress, yld, 1.3 mm/min, 50 mm span | 1060 | kgf/cm2 | ASTM D 790 | |

| Flexural Modulus, 1.3 mm/min, 50 mm span | 25400 | kgf/cm2 | ASTM D 790 | |

| Tensile Stress, yield, 50 mm/min | 65 | MPa | ISO 527 | |

| Tensile Stress, break, 50 mm/min | 50 | MPa | ISO 527 | |

| Tensile Strain, yield, 50 mm/min | 4 | % | ISO 527 | |

| Tensile Strain, break, 50 mm/min | 90 | % | ISO 527 | |

| Tensile Modulus, 1 mm/min | 2600 | MPa | ISO 527 | |

| Flexural Stress, yield, 2 mm/min | 96 | MPa | ISO 178 | |

| Flexural Modulus, 2 mm/min | 2500 | MPa | ISO 178 | |

| IMPACT | Value | Unit | Standard | |

| Izod Impact, notched, 23°C | 71 | cm-kgf/cm | ASTM D 256 | |

| Izod Impact, notched, -30°C | 17 | cm-kgf/cm | ASTM D 256 | |

| Instrumented Impact Total Energy, 23°C | 662 | cm-kgf | ASTM D 3763 | |

| Izod Impact, notched 80*10*3 23°C | 20 | kJ/m2 | ISO 180/1A | |

| Izod Impact, notched 80*10*3 -30°C | 10 | kJ/m2 | ISO 180/1A | |

| Izod Impact, notched 80*10*4 23°C | 25 | kJ/m2 | ISO 180/1A | |

| Izod Impact, notched 80*10*4 -30°C | 10 | kJ/m2 | ISO 180/1A | |

| Charpy 23°C, V-notch Edgew 80*10*3 sp=62mm | 20 | kJ/m2 | ISO 179/1eA | |

| Charpy -30°C, V-notch Edgew 80*10*3 sp=62mm | 10 | kJ/m2 | ISO 179/1eA | |

| Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm | 22 | kJ/m2 | ISO 179/1eA | |

| THERMAL | Value | Unit | Standard | |

| Vicat Softening Temp, Rate B/50 | 110 | °C | ASTM D 1525 | |

| HDT, 0.45 MPa, 3.2 mm, unannealed | 100 | °C | ASTM D 648 | |

| HDT, 1.82 MPa, 3.2mm, unannealed | 89 | °C | ASTM D 648 | |

| HDT, 1.82 MPa, 6.4 mm, unannealed | 99 | °C | ASTM D 648 | |

| CTE, -40°C to 40°C, flow | 7.5E-05 | 1/°C | ASTM E 831 | |

| CTE, -40°C to 40°C, xflow | 7.5E-05 | 1/°C | ASTM E 831 | |

| Thermal Conductivity | 0.2 | W/m-°C | ISO 8302 | |

| CTE, -40°C to 40°C, flow | 7.5E-05 | 1/°C | ISO 11359-2 | |

| CTE, -40°C to 40°C, xflow | 7.5E-05 | 1/°C | ISO 11359-2 | |

| Ball Pressure Test, 75°C /- 2°C | Pass | - | IEC 60695-10-2 | |

| Vicat Softening Temp, Rate B/50 | 110 | °C | ISO 306 | |

| Vicat Softening Temp, Rate B/120 | 113 | °C | ISO 306 | |

| HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm | 93 | °C | ISO 75/Af | |

| Relative Temp Index, Elec | 90 | °C | UL 746B | |

| Relative Temp Index, Mech w/impact | 90 | °C | UL 746B | |

| Relative Temp Index, Mech w/o impact | 90 | °C | UL 746B | |

| PHYSICAL | Value | Unit | Standard | |

| Specific Gravity | 1.19 | - | ASTM D 792 | |

| Mold Shrinkage, flow, 3.2 mm (5) | 0.4 - 0.6 | % | SABIC Method | |

| Melt Flow Rate, 260°C/2.16 kgf | 18 | g/10 min | ASTM D 1238 | |

| Density | 1.2 | g/cm3 | ISO 1183 | |

| Water Absorption, (23°C/sat) | 0.2 | % | ISO 62 | |

| Moisture Absorption (23°C / 50% RH) | 0.1 | % | ISO 62 | |

| Melt Volume Rate, MVR at 260°C/2.16 kg | 15 | cm3/10 min | ISO 1133 | |

| ELECTRICAL | Value | Unit | Standard | |

| Hot Wire Ignition {PLC) | 3 | PLC Code | UL 746A | |

| High Ampere Arc Ign, surface {PLC} | 0 | PLC Code | UL 746A | |

| Comparative Tracking Index (UL) {PLC} | 3 | PLC Code | UL 746A | |

| Volume Resistivity | >1.E 15 | Ohm-cm | IEC 60093 | |

| Surface Resistivity, ROA | >1.E 15 | Ohm | IEC 60093 | |

| Dielectric Strength, in oil, 0.8 mm | 35 | kV/mm | IEC 60243-1 | |

| Dielectric Strength, in oil, 1.6 mm | 25 | kV/mm | IEC 60243-1 | |

| Dielectric Strength, in oil, 3.2 mm | 17 | kV/mm | IEC 60243-1 | |

| FLAME CHARACTERISTICS | Value | Unit | Standard | |

| UL Recognized, 94V-1 Flame Class Rating (3) | 0.6 | mm | UL 94 | |

| UL Recognized, 94V-0 Flame Class Rating (3) | 0.75 | mm | UL 94 | |

| UL Recognized, 94-5VA Rating (3) | 3 | mm | UL 94 | |

| UL Recognized, 94-5VB Rating (3) | 1.5 | mm | UL 94 | |

| Glow Wire Flammability Index 960°C, passes at | 0.75 | mm | IEC 60695-2-12 | |

| Glow Wire Flammability Index 960°C, passes at, by VDE | 0.75 | mm | IEC 60695-2-12 | |

| Glow Wire Ignitability Temperature, 0.75 mm, by VDE | 775 | °C | IEC 60695-2-13 | |

| Glow Wire Ignitability Temperature, 1.0 mm | 825 | °C | IEC 60695-2-13 | |

| Glow Wire Ignitability Temperature, 1.5 mm, by VDE | 775 | °C | IEC 60695-2-13 | |

| Glow Wire Ignitability Temperature, 3.0 mm | 800 | °C | IEC 60695-2-13 | |

| Glow Wire Ignitability Temperature, 3.0 mm, by VDE | 775 | °C | IEC 60695-2-13 | |

| Oxygen Index (LOI) | 34 | % | ISO 4589 | |

1.汽车内外饰:仪表板,饰柱,仪表前盖,格栅,内外饰件 。

2.商务设备机壳和内置部件:笔记本/台式电脑,复印机,打印机,绘图仪,显示器。

3.电信,移动电话外壳,附件以及智能卡(SIM卡)。

4.电器产品,电子产品外壳,电表罩和壳体,家用开关,插头和插座,电缆电线管道。

5.家用电器,如洗衣机,吹风机,微波炉内外部件等。