东莞市轩涵塑胶原料有限公司

Physical PropertiesMetricEnglishCommentsMechanical PropertiesMetricEnglishCommentsThermal PropertiesMetricEnglishCommentsOptical PropertiesMetricEnglishComments

| Specific Gravity | 1.13 g/cc | 1.13 g/cc | ASTM D792 |

| Water Absorption | 0.35 % @Time 86400 sec |

0.35 % @Time 24.0 hour |

Immersion; ASTM D570 |

| Water Vapor Transmission | 132 g/m2/day | 8.50 g/100 in2/day | ASTM F372 |

| Oxygen Transmission Rate | 841 cc/m2/day @Pressure 0.101 MPa, Temperature 30.0 °C |

54.2 cc/100 in2/day @Pressure 14.7 psi, Temperature 86.0 °F |

ASTM D1434 |

| Viscosity Measurement | 1.05 | 1.05 | Inherent; EMN-A-AC-G-V-1 |

| Thickness | 130 microns | 5.12 mil | |

| Melt Flow | 20 g/10 min @Load 2.16 kg, Temperature 230 °C |

20 g/10 min @Load 4.76 lb, Temperature 446 °F |

ASTM D1238 |

| Hardness, Shore A | 95 | 95 | ASTM D2240 |

| Hardness, Shore D | 55 | 55 | ASTM D2240 |

| Tensile Strength at Break | 20.0 MPa | 2900 psi | ASTM D638 |

| Film Tensile Strength at Yield, MD | 13.7 MPa | 1990 psi | ASTM D882 |

| Film Tensile Strength at Yield, TD | 13.5 MPa | 1960 psi | ASTM D882 |

| Tensile Strength, Yield | 14.0 MPa | 2030 psi | ASTM D638 |

| Film Elongation at Break, MD | 550 % | 550 % | ASTM D882 |

| Film Elongation at Break, TD | 550 % | 550 % | ASTM D882 |

| Film Elongation at Yield, MD | 26 % | 26 % | ASTM D882 |

| Film Elongation at Yield, TD | 26 % | 26 % | ASTM D882 |

| Elongation at Break | 300 % | 300 % | ASTM D638 |

| Elongation at Yield | 30 % | 30 % | ASTM D638 |

| Tensile Modulus | 0.170 GPa | 24.7 ksi | ASTM D638 |

| Flexural Modulus | 0.150 GPa | 21.8 ksi | ASTM D790 |

| Izod Impact, Notched | 0.500 J/cm @Temperature -40.0 °C |

0.937 ft-lb/in @Temperature -40.0 °F |

ASTM D256 |

| Coefficient of Friction | >= 1.0 | >= 1.0 | ASTM D1894 |

| Tear Strength, Total | 370 N | 83.2 lb (f) | ASTM D1004 |

| Film Tensile Strength at Break, MD | 23.7 MPa | 3440 psi | ASTM D882 |

| Film Tensile Strength at Break, TD | 22.6 MPa | 3280 psi | ASTM D882 |

| Tangent Modulus | 179 MPa | 26000 psi | T.D.; ASTM D882 |

| 185 MPa | 26800 psi | M.D.; ASTM D882 | |

| Torsional Stiffness |

240 MPa @Temperature -28.0 °C |

34800 psi @Temperature -18.4 °F |

ASTM D1043 |

| 930 MPa @Temperature <=-70.0 °C |

135000 psi @Temperature <=-94.0 °F |

ASTM D1043 | |

| Heat of Fusion | 27.0 J/g | 11.6 BTU/lb | ASTM E793 |

| CTE, linear | 150 μm/m-°C | 83.3 μin/in-°F | ASTM D696 |

| Specific Heat Capacity |

1.60 J/g-°C @Temperature 25.0 °C |

0.382 BTU/lb-°F @Temperature 77.0 °F |

solid; DSC |

| 1.80 J/g-°C @Temperature 100 °C |

0.430 BTU/lb-°F @Temperature 212 °F |

solid; DSC | |

| 2.00 J/g-°C @Temperature 150 °C |

0.478 BTU/lb-°F @Temperature 302 °F |

solid; DSC | |

| 2.30 J/g-°C @Temperature 175 °C |

0.550 BTU/lb-°F @Temperature 347 °F |

solid; DSC | |

| 2.30 J/g-°C @Temperature 225 °C |

0.550 BTU/lb-°F @Temperature 437 °F |

melt; DSC | |

| 3.10 J/g-°C @Temperature 200 °C |

0.741 BTU/lb-°F @Temperature 392 °F |

transition; DSC | |

| Thermal Conductivity | 0.190 W/m-K | 1.32 BTU-in/hr-ft2-°F | ASTM C177 |

| Melting Point | 207 °C | 405 °F | Crystalline Peak; ASTM D3418 |

| Crystallization Temperature | 140 °C | 284 °F | DSC |

| Vicat Softening Point | 170 °C @Load 1.00 kg |

338 °F @Load 2.20 lb |

ASTM D1525 |

| Brittleness Temperature | <= -75.0 °C | <= -103 °F | ASTM D746 |

| Glass Transition Temp, Tg | -3.00 °C | 26.6 °F | DSC |

| Refractive Index | 1.51 @Wavelength 589.3 nm |

1.51 @Wavelength 589.3 nm |

nD; ASTM D542 |

| Haze | 1.0 % | 1.0 % | for Film; ASTM D1003 |

| Gloss | 80 % | 80 % | for Film, 45°; ASTM D2457 |

| Transmission, Visible |

90 % @Thickness 0.130 mm |

90 % @Thickness 0.00512 in |

Regular, Film; ASTM D1003 |

| 93 % @Thickness 0.130 mm |

93 % @Thickness 0.00512 in |

||

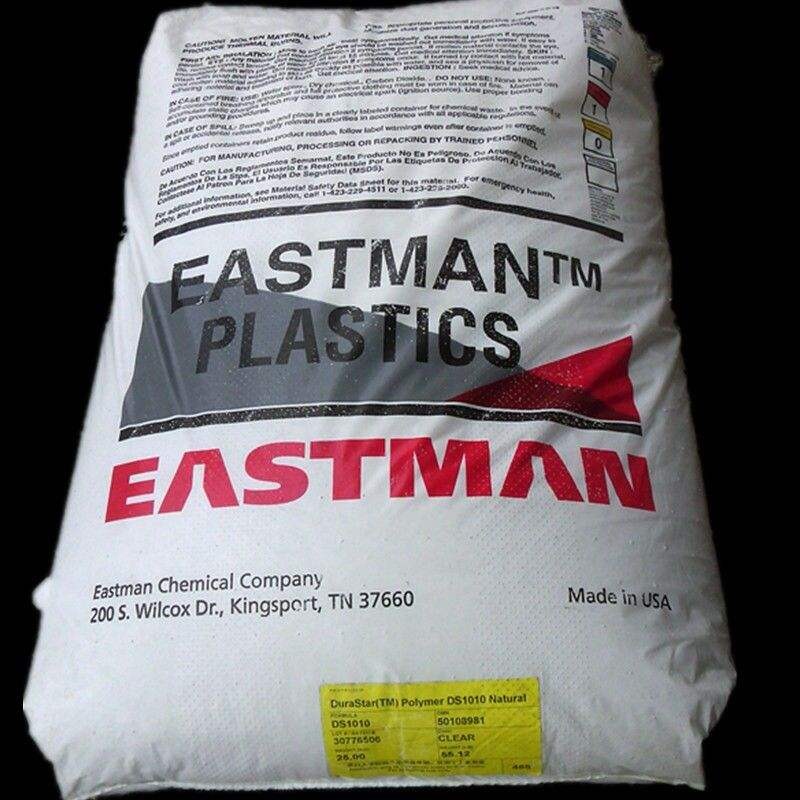

本公司长期专业代理销售 美国伊士曼 PETG 塑料等多种牌号产品

我司产品均可免费提供详细物性表(英文和中文版)、加工参数表、ROHS(SGS)、物质安全表MSDS、UL黄卡及FDA认证等相关资料;可开17%增值税发票;免费为客户分析样版并提供原料型号咨询服务(可免费帮客户翻译英文资料);如需试料、了解产品相关信息及当日报价,敬请来电、来邮及在线咨询,竭诚为您服务!

由于市场行情波动大,详细价格请旺旺QQ或者来电咨询,为此造成的不便,请您谅解。

★★郑重承诺:本公司所售原料全部为原厂原包正牌料、杜绝一切副牌料、水口料以次充好★★★

联系方式:

手机:13929219083

QQ:1916872373 邮箱:1916872373@qq.com